|

|

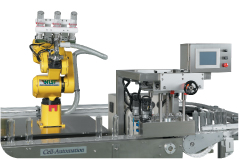

Linear-type bottle reversing air washing machines with preeminent support performance for new products and high washing capability |

|

| A pitch maker that provides preeminent support performance for new products along with a highly reliable FANUC robot cleans bottles with compressed air while reversing the bottles, thus demonstrating a high washing effect. |

|

|

|

|

|

|

|

|

A compact linear-type that requires less space than conventional machines and can be incorporated into existing lines with ease. |

|

|

| |

|

|

WIST's unique pitch maker enables bottles to be quarried and stably conveyed without the use of screws, star wheels, or holders.

|

|

|

| |

|

|

Not requiring any changeover of parts, thus immediately supporting new products with expenses saved. |

|

|

| |

|

|

Bottles are reversed after the openings of the bottles are plugged and vacuumed, which makes it possible to clean the heavy dust in the bottles, such as glass dust, without dispersing the dust. |

|

|

| |

|

|

WIST's support software enables data input on new products into the robot and the position adjustment of the robot with ease through a touch panel, thus eliminating complicated teaching work and allowing ease of use on site. |

|

|

|

|

| Production capability |

WS-4R: Approximately 40/min

WS-6R: Approximately 60/min

WS-8R: Approximately 80/min |

| Washing system |

Clean air purge of bottles turned upside down and

blower recovery |

| Air purge filter |

Micro-mist air filter (0.01fÊm element) |

| Blower recovery filter |

Dry type filter |

| Applicable bottles |

Diameter: 30 to 80 mm, Height: 60 to 200 mm |

| Safety cover |

Under waist: SUS cover,

Above waist: 5-mm-thick PET

(provided with opening/closing interlock) |

| Options |

Electrostatic remover, high-performance filter for air

purging, HEPA filter for exhaust gas,

support for clean robot specifications, and upstream

and downstream side belt conveyor |

| Safety devices |

Door opening and closing interlock and emergency

stop switch |

| Utilities |

Electricity: 30 A at 200 VAC, Air: 0.5 MPa min. |

|

| The inquiry over the telephone |

TEL 81-774-98-6767 |

| The inquiry by the email |

khara@wist.co.jp |

| The inquiry from the website |

|

|

|

|

|

|